Modern motorbikes increasingly rely on sophisticated fuel injection systems, often referred to as Programmed Fuel Injection (PGM-FI), to deliver optimal performance, fuel efficiency, and reduced emissions. These systems are a significant leap forward from older carburetor designs, offering precise control over the air-fuel mixture. However, like any advanced technology, fuel injection systems require proper maintenance to function flawlessly. Neglecting this crucial aspect can lead to a myriad of performance issues, from decreased fuel economy to a complete breakdown. Understanding the intricacies of your bike’s fuel injection system and recognizing the signs of potential problems is vital for every motorbike owner.

We will delve into the workings of these systems, common issues they face, and how regular maintenance, particularly clean fuel injection services, can prevent costly repairs. We will explore the various components, how problems manifest, and the diagnostic tools used to identify them. Furthermore, we will highlight how Big Jose Motorbike Services can be your trusted partner in maintaining your bike’s peak performance, offering expert solutions for issues like a faulty fuel sensor or a bike that struggles to start. Our aim is to empower you with the knowledge to keep your motorbike running smoothly and reliably.

What is a fuel injection system OR PGM-FI

A fuel injection system, or PGM-FI as it’s commonly known, is an advanced electronic system designed to precisely control the amount of fuel delivered to the engine’s combustion chamber. Unlike traditional carburetors, which operate mechanically based on air pressure, fuel injection systems use electronic sensors and a computer, the Engine Control Unit (ECU), to determine the ideal fuel-to-air ratio for varying engine conditions. This precise control results in significant improvements in fuel efficiency, a reduction in harmful emissions, and enhanced engine performance across the entire RPM range. The system continuously monitors factors like engine temperature, throttle position, and ambient air pressure to ensure the engine always receives the optimal fuel mixture for efficient and complete combustion. This adaptability is what makes PGM-FI superior to older fuel delivery methods.

The fundamental principle behind PGM-FI is the atomization of fuel into a fine mist before it enters the engine, which promotes more efficient combustion. This atomization is achieved by the fuel injection nozzle, which sprays fuel under high pressure into the intake manifold or directly into the cylinder. The ECU meticulously controls the timing and duration of this fuel spray. For instance, during a cold start, the ECU might enrich the mixture to aid ignition, while during steady cruising, it will lean the mixture to maximize fuel economy. This dynamic adjustment ensures optimal performance regardless of environmental conditions or rider input, offering smoother acceleration, better throttle response, and more consistent power delivery.

What are components of FI system and how they work

The fuel injection system is composed of several critical components that work in unison to deliver fuel to the engine. At its core is the fuel injector itself, an electronically controlled valve responsible for spraying a precise amount of fuel into the engine. The injector’s ability to atomize fuel into a fine mist is crucial for efficient mixing with air and complete combustion. If the injector becomes clogged or malfunctions, the fuel spray pattern can be compromised, leading to poor combustion, reduced power, and increased fuel consumption. Therefore, keeping the fuel injection nozzle clean and free from deposits is paramount for optimal engine performance. Regular maintenance helps prevent such blockages.

The throttle body is another vital component, regulating the amount of air entering the engine. A throttle plate within the throttle body opens and closes in response to the rider’s throttle grip input, controlling airflow. As more air enters, the ECU signals the fuel injection system to deliver more fuel, resulting in increased power. The throttle body typically also houses the throttle position sensor, which relays the throttle’s opening angle to the ECU, providing essential data for fuel calculation. Sensors are indispensable to the entire system, including the fuel sensor for tank levels, the Idle Air Control Valve (IACV) for idle speed regulation, and various air sensors (MAP/MAF) that measure air density and volume. Each sensor plays a critical role in providing accurate data to the ECU, ensuring the engine runs efficiently and reliably, preventing issues like an unstable fuel mixture or the bike cutting out.

What problem fuel injection system usually has and why

Fuel injection systems, despite their efficiency, are prone to specific problems, primarily due to the gradual accumulation of deposits and the eventual wear of electronic components. One of the most common issues is clogged fuel injectors. Over time, varnish, carbon, and other impurities from fuel can build up on the injector nozzles, obstructing the precise spray pattern. This blockage leads to restricted or uneven fuel delivery, manifesting as a rough idle, hesitation during acceleration, reduced power, and notably worse fuel economy. When fuel is not properly atomized, combustion becomes inefficient, wasting fuel and contributing to further carbon deposits within the engine. This slow degradation often goes unnoticed until performance issues become significant, making clean fuel injection a vital preventative measure.

Another frequent problem arises from issues with the throttle body. Dirt, carbon, and oil residue can accumulate on the throttle plate and within the throttle bore, hindering its smooth operation. A sticky or restricted throttle plate can lead to an erratic idle, poor throttle response, and in severe cases, cause the bike to cutting out when the throttle is closed quickly. Furthermore, sensor malfunctions are a significant source of problems. A faulty fuel sensor might provide inaccurate fuel level readings, while a malfunctioning Idle Air Control Valve (IACV) can cause an unstable fuel idle, leading to the engine stalling at low speeds. Air sensors providing incorrect data can also lead to improper fuel-air mixtures, resulting in either excessive fuel consumption or potential engine damage due to a lean condition.

How to detect these problems with FI motor scanner

Diagnosing problems within a modern fuel injection system can be challenging without specialized equipment, given their intricate electronic nature. This is where an FI motor scanner, also known as a diagnostic tool or scan tool, becomes essential. These devices connect to your motorbike’s onboard diagnostic (OBD) port and communicate directly with the Engine Control Unit (ECU). The scanner can retrieve Diagnostic Trouble Codes (DTCs), which are specific codes stored by the ECU when it detects a malfunction in a sensor or component. Each DTC corresponds to a particular problem, allowing technicians to accurately pinpoint the area of concern, whether it’s a faulty fuel sensor, an issue with the fuel injection itself, or another sensor anomaly that might cause the bike not start.

Beyond simply reading trouble codes, advanced FI motor scanners offer extensive diagnostic capabilities. They can display real-time data streams from various sensors, enabling technicians to monitor parameters such as engine RPM, throttle position, oxygen sensor readings, and fuel pressure. By observing these live data points, experienced technicians can identify inconsistencies or values that fall outside the normal operating range, even if a specific trouble code hasn’t been triggered yet. For example, an erratic oxygen sensor reading might indicate a problem with the air-fuel mixture, while abnormal fuel pressure readings could point to a failing fuel pump or a clogged fuel injection system. This comprehensive data analysis is crucial for accurately diagnosing intermittent problems or issues that cause the bike to suddenly start cutting out.

How often and when should we clean up the fuel injection

Maintaining a clean fuel injection system is crucial for your motorbike’s longevity and optimal performance. While there isn’t a universally fixed schedule, a good general guideline suggests considering a clean fuel injection service every 10,000 to 15,000 kilometers, or at least once a year. This is especially true if you frequently ride in urban environments, where stop-and-go traffic can contribute to deposit buildup, or if you regularly use lower-quality fuel, which may contain more impurities. This proactive approach helps prevent the gradual accumulation of carbon deposits and varnish that can lead to significant performance issues. Consistent clean fuel injection ensures your engine continues to receive the precise fuel delivery it was designed for, leading to better fuel economy and a smoother riding experience.

Beyond a fixed schedule, certain symptoms unequivocally indicate that your fuel injection system requires immediate attention. If you notice your bike experiencing a rough or unstable fuel idle, particularly during cold starts, it’s a strong indicator of potentially dirty fuel injectors. Hesitation or a noticeable flat spot during acceleration, especially when you twist the throttle, also suggests that the injectors might not be delivering fuel efficiently. A sudden drop in fuel economy, where you find yourself filling up more frequently for the same distance, is another clear sign that your fuel injection system is becoming clogged. Furthermore, if your bike struggles to start, or if it feels like the engine is cutting out intermittently, particularly at low speeds, these are all strong indicators that your fuel injection system, or related sensors, require professional attention.

How much to clean up fuel injection

The cost of maintaining your fuel injection system is a worthwhile investment in your motorbike’s performance and longevity. At Big Jose Motorbike Services, we offer a comprehensive clean fuel injection package that includes fuel injection cleaning, fuel throttle cleaning, and a program reset for a competitive price of 220,000 VND. This transparent pricing ensures you know exactly what you’re paying for without any hidden charges. This service focuses on thoroughly removing carbon deposits and varnish from the critical components of your fuel system, ensuring optimal fuel delivery and air intake. This proactive maintenance helps prevent more significant problems down the line, ultimately saving you money on potential repairs and improving your bike’s overall efficiency. Considering the benefits, this cost is a modest investment for a smoother, more powerful ride.

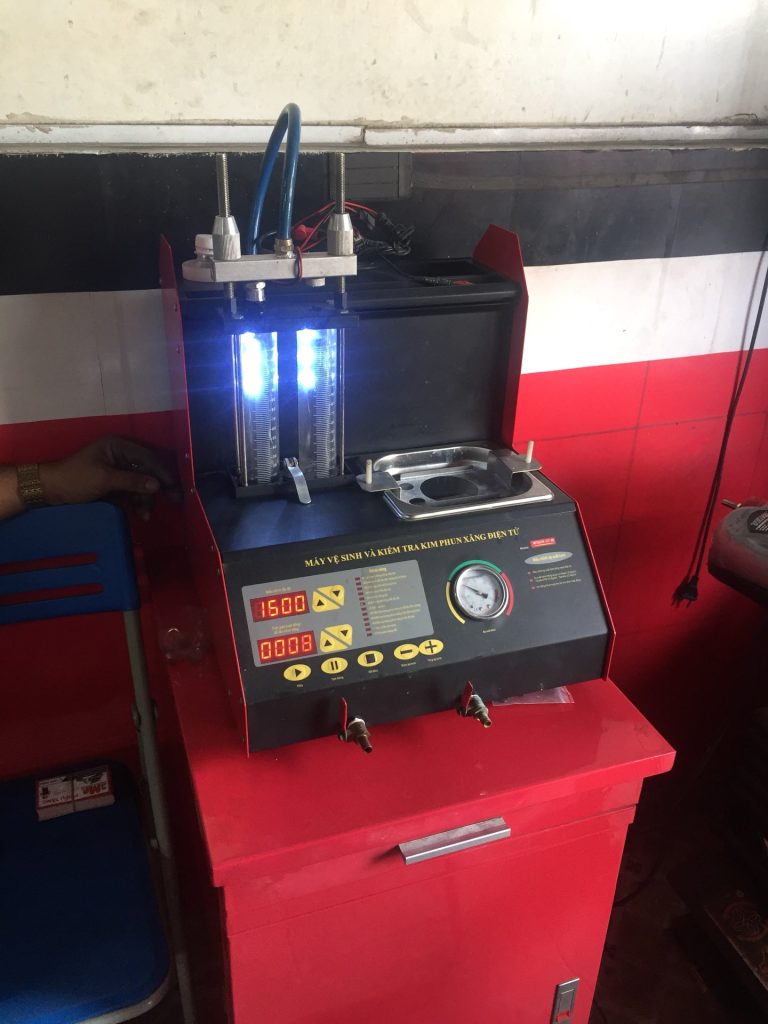

Our fuel injection cleaning process utilizes specialized equipment and effective cleaning agents designed to safely dissolve stubborn deposits without damaging delicate components. This includes a thorough cleaning of the fuel injection nozzle, ensuring it can spray fuel in a fine, even mist as intended. Simultaneously, the fuel throttle body is meticulously cleaned, removing any accumulated dirt or carbon that can hinder airflow and throttle response. A clean throttle body means a smoother idle and more precise control over acceleration. Furthermore, after the physical cleaning, our technicians perform a program reset using an FI motor scanner. This step is crucial because the Engine Control Unit (ECU) “learns” and adapts to the engine’s operating conditions. Resetting it allows the ECU to relearn and optimize fuel delivery for the now-clean system, maximizing the benefits of the clean fuel injection.

What happens when fuel injection sensors not working properly

When fuel injection sensors fail to function correctly, the entire precision of the system is compromised, leading to a cascade of negative effects on your motorbike’s performance. The Engine Control Unit (ECU) relies on accurate data from these sensors to calculate the optimal fuel-air mixture and ignition timing. If a sensor provides faulty information, the ECU will make incorrect adjustments, resulting in inefficient combustion. For instance, if the oxygen sensor sends a signal indicating a lean mixture when it’s actually rich, the ECU will add more fuel, leading to excessive fuel consumption, black smoke from the exhaust, and potentially carbon buildup on spark plugs. Conversely, if it falsely detects a rich mixture, the ECU will lean out the fuel, causing the engine to run hot, lose power, and potential internal damage due to detonation.

A faulty fuel sensor might not directly impact engine performance, but it can certainly leave you stranded. If the fuel sensor sends an inaccurate reading to your dashboard, showing more fuel than is actually in the tank, you could unexpectedly run out of gas in an inconvenient or dangerous location. While this might seem like a minor inconvenience, it can be a significant safety concern, especially on busy roads. Similarly, problems with the Idle Air Control Valve (IACV) can be particularly frustrating. A dirty or failing IACV can lead to an erratic or extremely low idle, causing the bike to constantly feel like it will cutting out when you stop or disengage the clutch. This can make riding in traffic or at slow speeds very difficult and even hazardous, as the engine might die unexpectedly, contributing to an unstable fuel delivery experience.

How much to replace fuel injection sensors

The cost of replacing fuel injection sensors varies significantly depending on the specific sensor that needs attention and the make and model of your motorbike. Generally, individual sensors like the oxygen sensor, throttle position sensor, or temperature sensor can range from a few hundred thousand VND to over a million VND for the part alone. Labor costs for diagnostics and installation would be added on top of this. For example, a common oxygen sensor might cost around 500,000 VND to 1,000,000 VND, while a more complex MAP sensor could be closer to 1,500,000 VND or more. It is crucial to remember that these are approximate figures, and actual prices may differ based on the brand of the sensor and the specific motorbike model. Always get a clear quote from a reputable service center to avoid surprises.

Replacing a fuel sensor, which primarily measures the fuel level in the tank, is typically less expensive than performance-critical sensors. These usually cost in the range of 300,000 VND to 700,000 VND for the part itself, plus labor for installation. While a faulty fuel sensor doesn’t directly affect engine performance, it can cause significant inconvenience, making it difficult to accurately gauge your remaining fuel. The replacement process for many sensors often involves removing a few bolts and disconnecting an electrical connector, but some sensors may require more extensive disassembly of surrounding components, which can increase labor costs. In some severe cases, where multiple sensors fail or the problem is deeply rooted in the fuel injection system’s electronic controls, the overall cost could escalate, but regular diagnostics can often prevent such scenarios.

Big Jose have technical experts and tools to help you solve fuel injection problem

At Big Jose Motorbike Services, we understand the complexities of modern motorbike fuel injection systems and are fully equipped to handle any issue you might encounter. Our team comprises highly skilled and experienced technical experts who specialize in diagnosing and repairing fuel injection problems. They undergo continuous training to stay updated with the latest advancements in motorbike technology, ensuring they are proficient with various fuel injection systems across different brands and models. Whether your bike is experiencing an unstable fuel supply, struggling to start, or cutting out unexpectedly, our experts possess the knowledge and expertise to accurately identify the root cause of the problem, saving you time and frustration. We pride ourselves on providing reliable and efficient solutions for all your motorbike maintenance needs.

To complement our technical expertise, Big Jose Motorbike Services is outfitted with state-of-the-art diagnostic tools, including advanced FI motor scanners. These sophisticated devices allow us to perform comprehensive system checks, retrieve Diagnostic Trouble Codes (DTCs), and monitor real-time data from all critical sensors, such as the fuel sensor and air sensors. This precise diagnostic capability enables us to pinpoint even the most elusive fuel injection issues, from clogged injectors requiring a clean fuel injection service to faulty sensors necessitating replacement. Without these specialized tools, accurately diagnosing modern fuel injection systems would be incredibly difficult, often leading to guesswork and unnecessary repairs. Our commitment to investing in the right equipment ensures that we can provide accurate and effective solutions every time. Contact Big Jose Motorbike Services today! You can call us directly, text us to schedule an appointment, or simply make an appointment online through our website. Let our experts provide the professional care your fuel injection system deserves, ensuring your bike remains reliable and performs at its best on every ride.

Maintaining a healthy fuel injection system is paramount for the performance, efficiency, and longevity of your modern motorbike. From ensuring a consistent clean fuel injection process to promptly addressing faulty sensors, proactive maintenance is key to preventing major breakdowns and ensuring a smooth riding experience. Ignoring early warning signs like an unstable fuel delivery, your bike not start, or your engine cutting out can lead to more severe and costly problems down the line. Big Jose Motorbike Services is committed to providing top-tier fuel injection system diagnostics and repair. Our blend of expert technicians and advanced tools ensures that your motorbike receives the best possible care. Don’t wait for a small issue to become a big problem; schedule your regular service with us today.